Decrowning machines for the beverage industry

Remove crown corks with RINK

Efficiency & reliability – that’s what characterises our decrowning machines. Whether you want to uncork bottles in a crate or on a bottle conveyor – please contact us directly:

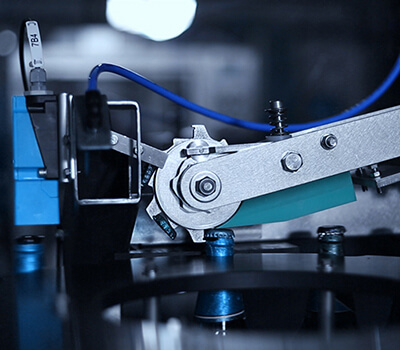

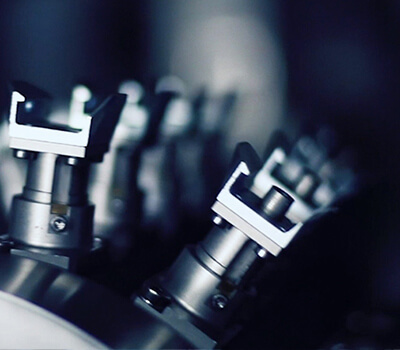

The decrowner

Crate decrowner

KM670

Rotation decrowner

RK940

Single bottle decrowner

EN940

Advantages of decrowning machines for the beverage industry

Thorough cleaning of returnable bottles is an important quality criterion for every beverage bottler in order to be able to bottle a top-quality product. To achieve this, it is absolutely essential that all beverage bottles are run through the washing machine without crown corks.

Our uncorking machines ensure that all bottles are reliably uncorked and can then be optimally cleaned.

Efficiency & reliability

Reusable & recycling

Questions about our decrowner?

Dr Michael Bäcker

RINK machines for decrowning bottles

State-of-the-art technologies for the beverage industry

Since we have also transferred the rotary concept to the decrowning of bottles on the bottle conveyor, we can now offer you these types of machines for removing crown corks:

Our customer projects and application examples

Decrowning machines from RINK

1967

The foundation

When crown corks were still removed by hand, company’s founder Wilhelm RINK thought that this activity could be performed more efficiently by machine. This is how the company RINK was founded and the crate decrowner established.

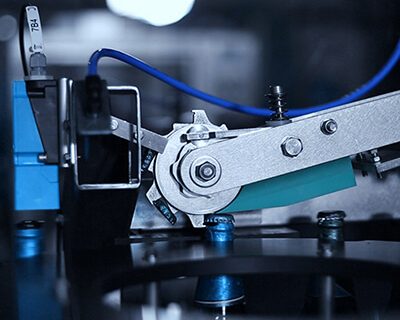

1995

Mechanical engineering sets new standards

Many years later, Jochen Bäcker, who had taken over the company with his wife Ursula Bäcker, the daughter of the founder, came up with the idea of removing the cork by a rotary movement, similar to a hand opener. The first rotation decrowning machine was commissioned successfully. This principle makes it possible to decrown up to 4,500 crates per hour.

2002

Transfer of the rotary concept to the uncorking of bottles on the bottle conveyor.

2012

RINK’s performance in the field of decrowning machines for the beverage industry in recent years has earned the company the title of “world market leader in removing crown corks“. To date, more than 200 machines of this type are successfully in use worldwide.