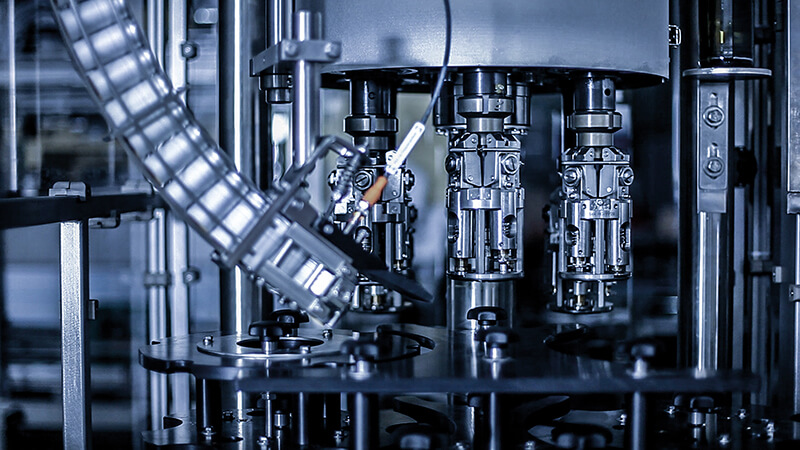

1-HEAD-CAPPER

| Bottle shape | cylindrical and shaped bottles |

| Bottle height / diameter | from 120 mm up to 400 mm |

| Cap types | all marketable caps of 28x15, 28x44, 30x60, 31,5x18, etc. (also with spout), VINO-LOK, STELVIN-LUX, ZORK |

| Integration | easy to integrate into an existing conveyor, no own conveyor drive |

| Capping | 1,6 rotations in lowest working point as requested by cap manufacturers |

| Capping head | top-quality capping head, 2 threaded rolls/ 2 flanged rolls; No cap – no contact (safety plunger) |

| Format change over | height easy adjustable by reference bottle on bottle plate, easy format parts, bottleneck star is adjusted with upper part |

| Performance | up to 3.000 bottles /h |

| Sorter | mechanical feeder with air support |

| Specialities | mechanical coupled electrical drive for capping- and stroke movements, bottleneck guiding mounted onto upper part, hygienic design with drive from above |

| Options | CO2 injection, feeding with elevator, air filter, electrical height adjustment |

| Type | VS-1 |

Applications & References

Several Maschinetypes