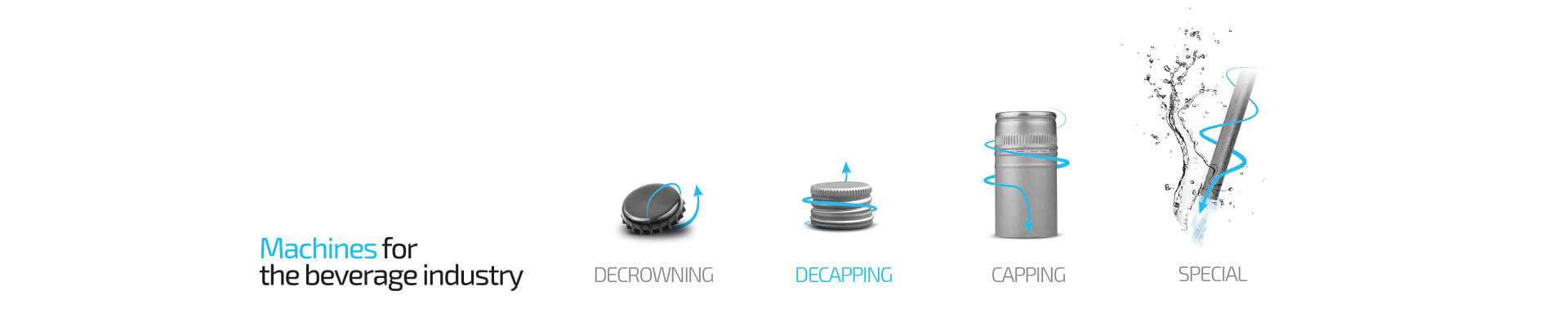

Soon after the market launch of the decrowner, customers made the request to RINK to decap bottles in crates. Until this time, screw caps were exclusively removed on the bottle conveyor. However, an expensive bottle separation after unpacking was necessary, which, in addition to the extensive space requirement, also had a negative effect on the bottle buffer between the unpacker and the bottle washer.

With the introduction of the crate decapper in 1973, we surprised our customers with a space-saving solution in front of the unpacker. This type of machine has been continuously optimized over the years, and today it is available in all sizes up to a single-lane output of 4,000 crates per hour. It is expandable by decrowning functionality.

In 2010, a solution for single bottles was developed as request of many customers. Since then, RINK is the only company in the world that offers both: a decapper in the crate as well as on the bottle conveyor. Customers can choose the most economical machine without having to forego the proven quality of RINK:

Crate decapper KM 790

Crate decapper KM 790